We offer services for new installations, upgrades, and retrofits. We can assist you with all three.

Translate This Page

Model 300-X Feedback Control Loader System

The Model 300-X Feedback Control Loader System is designed to replace spring-type systems in existing flight control systems, as well as for use in new flight control systems. It offers several advantages over spring-type systems, including the ability to customize and trim it for each specific application and aircraft. Additionally, it is typically less expensive than mechanical spring-type systems and offers better feel and fidelity.

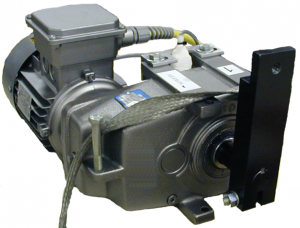

The 300-X Feedback Control Loader system includes a flight control model that works with a Host or in conjunction with MS Flight Simulator, Prepar3D, or X-Plane. It utilizes modified Helical gearboxes coupled with AC motors that use a closed feedback servo loop to provide the system with smooth and reliable performance. The gearbox is modified to reduce backlash to a minimum, but some minor friction and inertia are reflected in the flight controls (see table below).

This system is primarily designed for FAA Level 1 through 6 flight trainers. The system is certified for use in CRJ/737/A320 and Robinson R22/R-44 Trainers up to FAA Level 6. Modular electronics, coupled with a computer system and minimal cabling, ensure ease of installation, minimum maintenance, and longevity. All parts are COTS, and where required, are modified specifically for use in this application.

The 300-X Feedback Control Loader System is fully customizable for a variety of output torque requirements (refer to the table below). This allows for the same type of system to control a larger variety of controls, without having to rework documentation and engineering across multiple systems. The system is compatible with our 400-X Feedback Control Loader System and Motion Base Platform product line, providing a comprehensive and cohesive system for simulation training.

All systems come with a full one-year warranty and lifetime email/phone technical support. Extended warranties are also available.

For information on our software packages for this system, please click here.

Tried and True Design

Built to last... everything is COTS... everything is design to last practically forever! Proven reliability over decades of service.

Ease of Installation

With several models and designs to choose from, we work with you to get the job done... from design, manufacture and installation.

Unsurpassed Warranty

One year warranty on parts and LIFETIME technical support on every system from the moment it ships. Online documentation. Complete manuals.

Standard Torque Specifications – typical transport aircraft (KingAir):

| Axis | Peak | Continuous | Friction |

|---|---|---|---|

| Ailerons (Roll)* | 64 Lbs (86Nm) | 32 Lbs (43Nm) | 0.8 Lbs (1Nm) |

| Elevators (Pitch)* | 170 Lbs (230Nm) | 85 Lbs (115Nm) | 2.1 Lbs (2.7Nm) |

| Rudders (Yaw)* | 340 Lbs (460Nm) | 170 Lbs (230Nm) | 4.2 Lbs (5Nm) |

Standard Specifications for 300-X System include:

| Specification | Value |

|---|---|

| Velocity at the Pushrod: | 25 inches per second |

| Actuator Stroke | 5 inches max, 4 inches usable |

| Analog to Digital Converter | 16-bit resolution |

| Digital to Analog Converter | 16-bit resolution |

| Iteration Rate | 4Khz |

| Latency (gigabit Ethernet) | less than 1ms |

| Actuator Bandwidth | 30Hz |

Control System Modeling

Multi-Mass Modeling

Aircraft Measurement

Aircraft Dynamic Curves

Verification and Validation

Terrain and Nautical Applications

Steering Wheels

Joystick Controls

Rotary Wing System Applications

Collective Lever

Cyclic Stick

Directional Pedals

Fixed-Wing Systems Applications - FAA Level 6

Flight Stick, Wheel & Column

Rudder Pedals

Throttle Controls

Auto-Pilots

Trim and Tillers

Flight Control Software Model:

The software model is based on the flight model provided with centering springs added if required. The model is designed so that it can be tuned from the Host, thus it could be used for any light aircraft or transport. Except for setting the scale factors for position and force, this model will not need to be tuned to each specific application.

Control Parameters from Host:

Dynamic pressure, roll rate, pitch rate, yaw rate, dynamic pressure divided by velocity, boost oil pressure, autopilot command, autopilot engage, weight on nose wheel, nose wheel velocity, and nose wheel angle.

Safety:

The safety system in the control loader monitors the output to the DAC that drives the electronics. Monitoring the DAC allows the safety software to abort the system if the command to the electronics is excessive. In addition to the analog variables monitored by the safety software, the enable command to the electronics has a one-shot that must be continuously re-triggered by the software. Should the software halt for any reason, the one-shot will time out and the loader will abort. E-Stop safety switches can be utilized for a mechanical abort.

Interfaces:

Several interfaces are available: Bit 3, Ethernet, DR-11W (Concurrent), HSD (Encore), and UBC (Universal Bus Controller, Harris). Bit 3 is the easiest to use, Ethernet is the lowest cost for hardware. RS-232 can be used for some applications. Ethernet is typical.

Options:

This system can provide a nose wheel steering simulation, trim, tiller, throttle and a seat shaker option. Auto-Pilot integration is available upon request.

Power Requirements:

115 (230) volts, 7 (3.5) amps peak per axis

115 (230) volts, 1 (0.5) amps quiescent per axis

115 (230) volts, 3 (1.5) amps for the processor