Aircraft, Automobile, Maritime Trainers to Satellite Antenna Testing, Entertainment Rides (VR) and Medical Testing

Your Imagination is the Limit!

Translate This Page

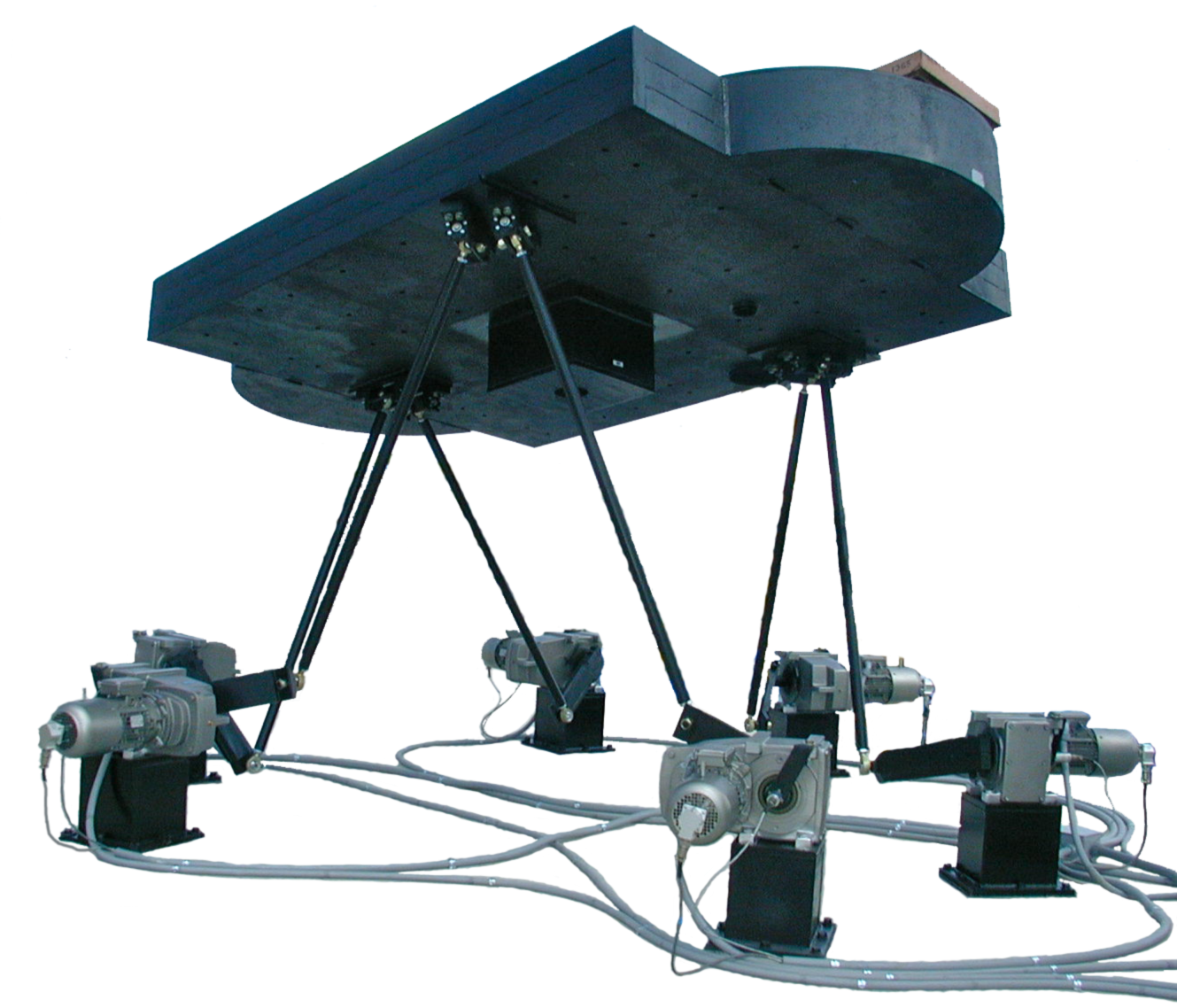

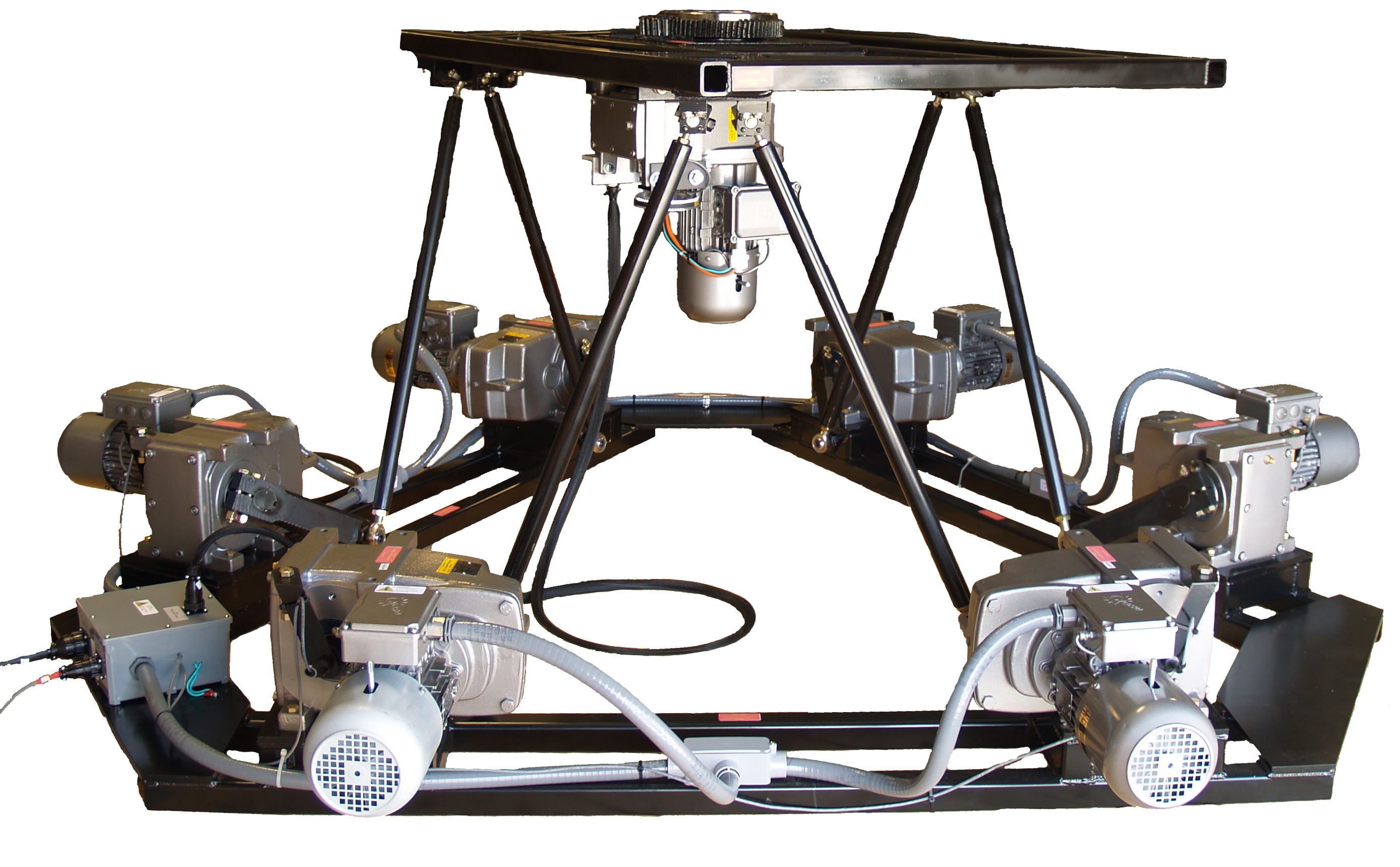

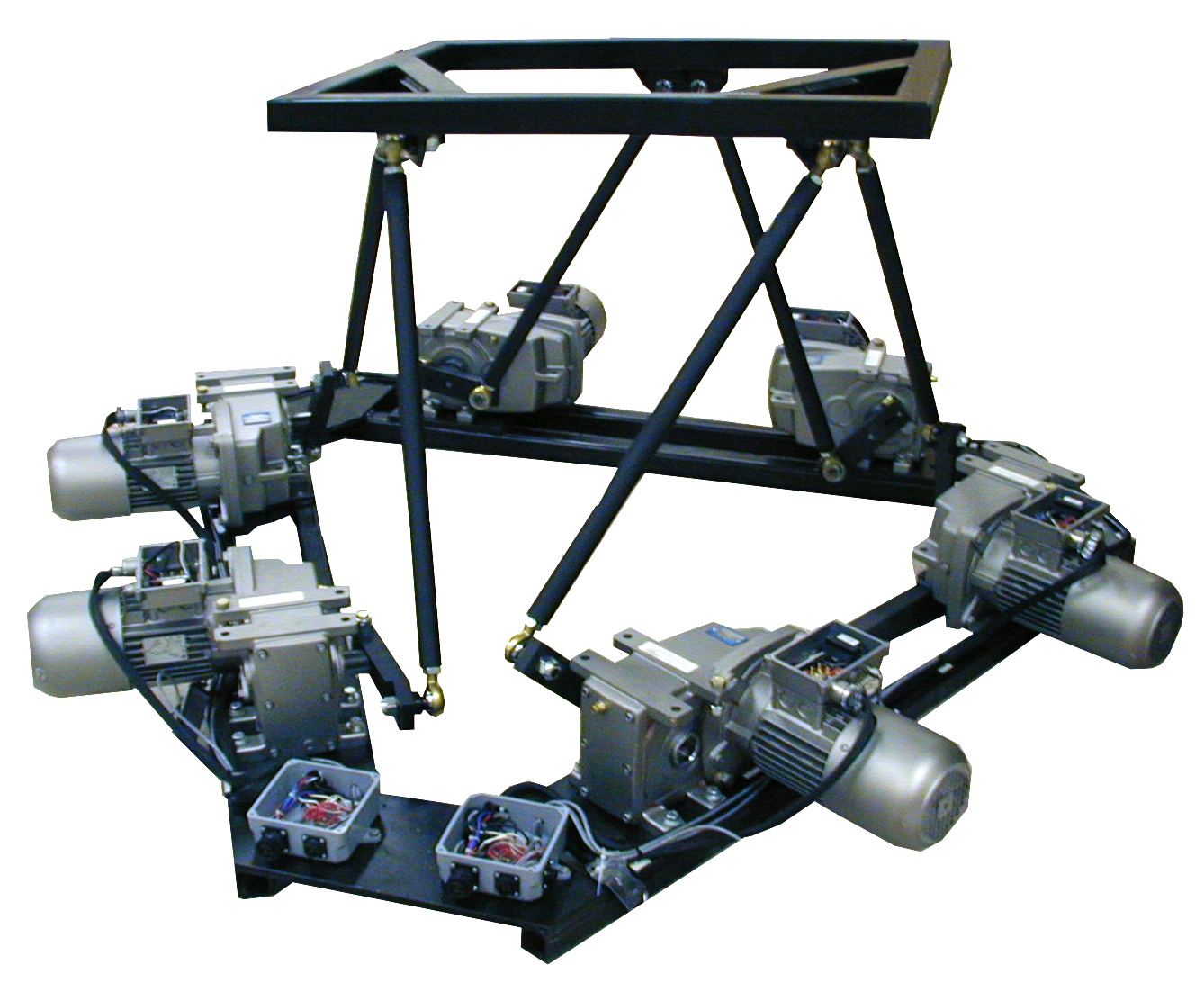

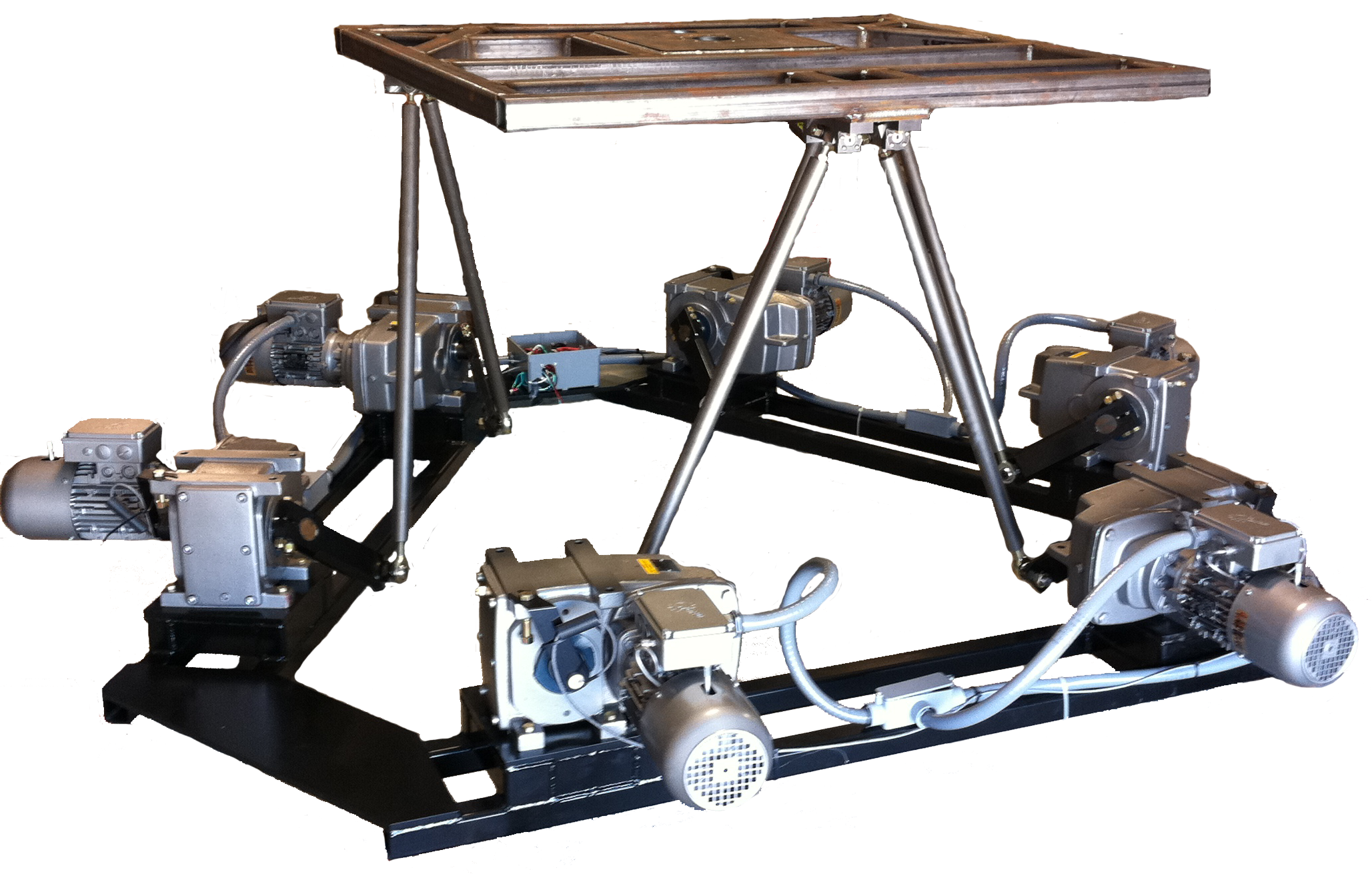

Six Axis (6DOF) Motion Base Platform Systems 710-6

We offer a wide range of six-axis (6dof) motion base platforms that come in different models and weight capacities. Our motion-based systems are customizable to suit your specific application needs and all come with an integrated top platform that can be modified to fit your requirements. We can pre-drill the top for you if you're planning to add seats, cockpits, cabins, or equipment (additional cost does apply).

Our six-axis (6dof) motion platform systems are designed for military, commercial, and entertainment applications. They are fully electric, digitally controlled, and require minimal maintenance. They are also environmentally friendly, reliable, and safe to use.

Our motion platform systems are highly efficient and have the lowest cost of ownership in the industry. They are built to last and can withstand harsh conditions, thanks to their fully sealed design.

Our motion base platforms come in different weight capacities starting from 500 pounds (227 Kgs) all the way up to 8000 pounds (1818 Kgs). The 500 lbs six-axis bases are meant for gaming rides, car simulators, seat shakers, virtual reality entertainment, or other small equipment testing applications. The 1,000 lbs six-axis bases are designed for rides accommodating 1-4 people near the center of the base. The 2,000 lb. or larger payload six-axis bases are designed to accommodate the top with several seats, including the walkway. The 4500 and 8000 lb. six-axis motion base platform systems can be used for large-scale entertainment rides and FAA level D Full-Flight Simulators.

We can also accommodate other combinations of strokes and payloads at an additional cost based on the contract.

Six Axis (6DOF) Motion Base Platform - Basics

A six axis motion base platform has the following axes: roll, pitch, heave, yaw, surge, and sway.

All motion base platforms are servo-controlled... which means that there is a closed feedback loop between the motor and the motor controller (drive amplifier). When the system receives a signal from either the computer or an analog control voltage, the motor moves in relation to the input signal (typically ±7.5v). If it receives a negative voltage, the crank on the motor moves down; a positive voltage, the crank moves up. There are no encoders, no limits, or stop for the upper and lower positions as there are in linear systems as none is required.

What is Included?

All motion base platform systems come with integrated electronics installed in COTS rack mount chassis which makes for ease of installation. Up to 50' of cables are included to interface the electronics to the motion base. Hubbell standard 220VAC plug, mating input connector, and generic system manual are included. Integrated safety braking system and e-stop integration are standard for every system. A standard system manual (ICD and maintenance) with a full drawing set is included. All systems come with a full one year warranty and lifetime email/phone technical support. For more information on our warranty, please click here. Extended warranties are available.

For information on our software packages for this system, please click here.

Design & Reliability - Proven!

Decades of reliable service in any environment.

No Maintenance...

Made to Last.

Environmentally Friendly

No hydraulics. Energy Efficient. No rare materials.

Completely recyclable or reusable.

Axis Layouts for Rotation for a Motion Base Platform

Mechanicals and Dynamics:

| Product Number | 710-6-500-220 | 710-6-1000-220 | 710-6-2000-220 | 710-6-4500-220 | 710-6-8000-220 |

|---|---|---|---|---|---|

| Payload Specification | 250 Kgs or 550 Lbs | 500 Kgs to 1100 Lbs | 1000 Kgs or 2200 Lbs | 2000 Kgs or 4400 Lbs | 3628 Kgs or 8000 Lbs |

| Standard Top Dimensions (customizable) | 304mm (12" sq) triangle | 660mm x 914mm (26" x 36") | 660mm x 914mm (26" x 36") | contract dependent | contract dependent |

| Bottom Dimensions for floor loading | 711mm sq (28" sq.) | 2133mm (84") circular footprint | 2133mm (84") circular footprint | contract dependent | contract dependent |

| Standard Height (customizable) | 482mm (19") | 812mm (32") | 812mm (32") | contract dependent | 1828mm (72") |

| Vertical Translation (Heave) | ±50mm (±2") | ±100mm (±4") | ±100mm (±4") | ±200mm (±8") | 762mm (30") total |

| Standard Angularity (customizable) | ±10 degrees (not-modifiable) | ±20 degrees (up to ±32 degrees) | ±20 degrees (up to ±32 degrees) | ±20 degrees (up to ±32 degrees) | ±20 degrees (up to ±32 degrees) |

| Standard Velocity (customizable) | ±60 deg/sec | ±100 deg/sec | ±100 deg/sec | ±100 deg/sec | ±100 deg/sec |

| Standard Acceleration (customizable) | ±100 deg/sec/sec | ±100 deg/sec/sec | ±100 deg/sec/sec | ±100 deg/sec/sec | ±100 deg/sec/sec |

| Standard Vertical Velocity (customizable) | ±10" /sec | ±10" /sec | ±10" /sec | ±10" /sec | ±10" /sec |

| Standard Vertical Acceleration (customizable) | 0.75g | 0.75g | 0.75g | 0.75g | 0.75g |

| Center of Gravity (overhung loads can be accommodated) | center of top | center of top | center of top | center of top | center of top |

Motion Base Platform Systems – Optional Control Systems

With any option, the system is plug and play ready!

With several different six-axis (6dof) motion base platform models to choose from, starting at 500 pounds (227 Kgs) and going up, they can be controlled in several different ways thanks to the system requiring a simple ±10VDC control input.

Computer Control– If the customer does purchase the computer system for control of the motion base, included with the computer is the control board, the input cable, operating system, keyboard, mouse, and maintenance software for the motion base. If the customer is purchasing the computer for entertainment ride profile playback and control, the computer can broadcast the video while running the motion base. Customers can specify video card output at contract time (for an additional cost). The 8000 pound or larger systems come with the computer standard.

Raspberry Pi and Phidgets– Since the motion base platform systems are controlled with an analog signal, they can be controlled with either a Raspberry Pi with a DAC installed or with a Phidget card such as the 1002_0B or OUT1002_0. With this option, enthusiasts with home-brewed flight simulators can interface the motion-based platform systems to Prepar3d, Flight Simulator Steam, or X-Plane. This option is not recommended for the larger systems as they do not provide enough fidelity.

Measurement Computing– all of the Measurement Computing ±10VDC analog output devices will work with any of the motion-based platform systems. Please check with our engineering department to get the fastest one available so that the motion-based platform performance is not hindered.

Sensoray 826 Card - this is our standard interface card. It handles all of our ADC, DAC, digital, and watchdog requirements for the motion base. It is included in the cost of the computer option listed above.

The customer is more than welcome to choose their interface. Be aware that if you require excellent movement of the system, 16-bit resolution on the DAC output is required. We are here to help with engineering and advice where and when you need it.

Power Requirements

Standard power requirements are 220VAC with other optional voltages available. The motion platforms are completely electric and environmentally green. The smaller bases can be configured to run from a standard 120 volt, 20 amp circuit with the use of a transformer (customer may purchase the transformer or we can provide at an additional cost). The mid-size bases (1,000 to 4,000 lbs) require 220 volt, either single phase or three phase and the largest bases (6,000 lbs and up) requiring from 220 to 440 volts AC, three phase. We can wire the system per customer specific electrical requirements.